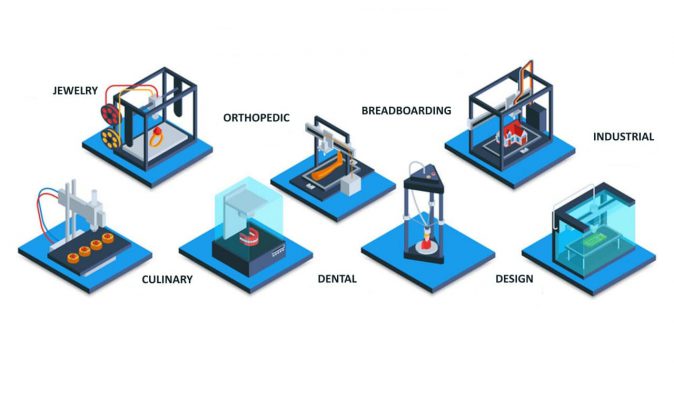

A locally focused and globally connected sector, Logistics is in continuous transformation towards improving technologies and solutions to better enable business outcomes and connecting the entire business ecosystem; and as such 3D printing is a fresh new territory that the logistics innovators have been betting on. This revolutionary technology has been deemed as one of the major disruptive trends to logistics and supply chain management, one that will radically change the social, economic and technical aspects of our industry. This technology is a game-changer in many ways, and there’s no question that there will be some impact on the logistics and shipping industry as a whole, so we will have to prepare for wind of change, and embrace the new opportunities as they present themselves.

The relationship between the logistics industry and 3D printing is fascinating for a multitude of reasons. The 3D in supply chain management integration seems natural, almost inevitable. Its potential applications within the production processes go hand in hand with the revolution that this technology has presented so far. 3D printing could bring massive changes to manufacturing processes and logistics functions such as global logistics, inventory levels, fulfillment processes, stock location, transportation routes and consumer relationships. It also has the potential to lower logistics and production costs leading to elimination of trade costs through localized production and substantial economic savings which in turn will reduce delivery times, satisfying customer demand, with a positive impact on the planet.

In places where entire manufacturing ecosystems produce goods in one particular area, 3D printing is expected to move there rather than to affect the location of production. Transport of bulk inputs for 3D printers will become extremely important, because 3D printing technology allows for local manufacturing. In other words, many parties and processes reliant on shipping in the past will no longer need it for the same purpose. But those same retailers will still need to acquire the printing materials from elsewhere. Further, if the goods are being sent to consumers or clients outside their local area, distribution networks will still be necessary with new the routes in mind, and so as a result the trade flows may change for some the goods but will not change for most of the goods. Take for example the case of millions of tons of seaborne trade of dry and liquid bulk goods such as petroleum, chemicals and large manufactured goods and foodstuff.

Logistics service providers are launching pilot projects to identify the potential need and possible options for adjusting their business models to include 3D printing services. Logistics operators, who have access to 3D printers, could provide the right materials for the printers and customize the product for the individual need of customers. Additionally they are responsible for the fast and safe delivery of the product in right place on right time. Transportation providers will need to become more flexible and agile to adapt to changes in logistics and the supply chain. Each logistics provider can achieve economies of scale by building up an owned network of shared 3D printers located in warehouses and distribution centers around the world. As manufacturers become accustomed to their production processes and supply chains, this will open new opportunities and will also challenge logistics providers to find new customer-centric solutions. Capital projects and investments in transportation facilities may need to be re-prioritized to reflect shifting changes in logistics and the supply chain.

Logistics providers anticipate the implications of 3D printing on global supply chain dynamics, and set them for their own transformational journey to strengthen their role within the broader value chain and offer their customers new solutions. Some of the more prevalent implication of 3D printing on the Global Logistics Industry could be listed as below:

⬜ There will be changes in the patterns of global goods transportation, both in terms of volume and flow. The volume of sea, air and land transport will be reduced in certain products, but will increase in others. The identity of the transported items will change. For example, for sure the transportation of raw materials related to 3D printing will arise.

⬜ The “mass customization” of products would mean that inventory levels fall, as goods are made to order. This would have the effect of reducing warehousing and inventory requirements.

⬜ A major new sector of the logistics industry would emerge dealing with the storage, movement and management of the raw materials which “feed” the 3D Printers.

⬜ The transportation cost saved of international logistics is most notable. Production costs and sales prices of most products and services will decrease significantly, while it becomes feasible to purchase local goods again. As near-shoring will be the norm, product life cycles might become shorter and easier to sustain.

⬜ Routes will likely shift as fewer finished products will be shipped from faraway origins. Goods no longer need to be shipped halfway around the world, because they can be printed out close to the consumer. Meanwhile, the importance of local production sites close to consumer markets will increase; this would mean an increase in “last mile” shipping.

The evolution in the supply chain dynamics will lead to the development of a new type of logistics services. The “new logistics provider” of the future will design solutions comprising demand planning, manufacturing, delivery, market monitoring, service parts management and return and recycling services. In essence, they will become Product Life-Cycle Management service providers. The most enlightened logistics companies could even become early adopters of the technologies – investing in the 3D printers and providing facilities for engineers – this would also provide a way of leveraging their capital and their own technological capabilities. Their businesses will comprise a mix of software development, delivery services, partner relationship management, contract management and brainpower. Organizations that are piloting and building a foundation for 3D printing now, will be best positioned to capture future value.